Why We’re Choosing Resin for Our Cast Surfaces

At Stratum Marquetry, sustainability is at the heart of everything we do. 100% of our Modern Marquetry starts with reclaimed or recycled materials, carefully crafted into something new. But one challenge we face is what to do with our smallest Modern Marquetry offcuts — the absolute end of line offcuts, that are just too small to be re-purposed - a mix of wood, plywood, plastics and other reclaimed materials.

We’re left with a choice:

Throw them away (sending mixed materials to landfill, where most cannot be recycled), or

Use a resin-based material to turn them into strong, long-lasting cast surfaces.

Why This Dilemma Exists

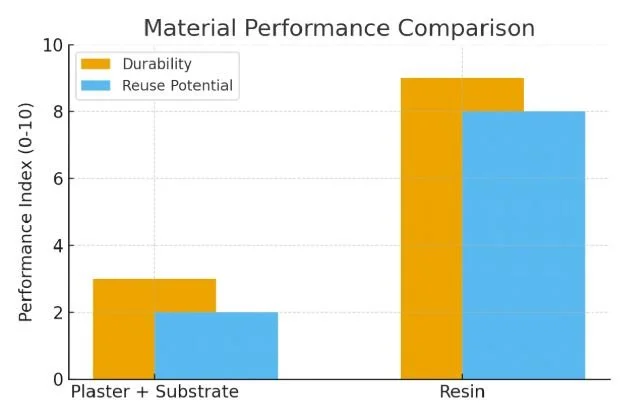

We first tried what looked like the more eco-friendly option: plaster. While plaster seemed ideal in principle, in practice it didn’t perform perfectly. It isn’t hard enough, doesn’t bond properly to every type of offcut (especially plastics and mixed materials), and crucially, it doesn’t produce surfaces that are strong enough to take back and reuse in the future.

That left us with two options: continue discarding offcuts, or explore resin.

The Problem with Throwing Offcuts Away

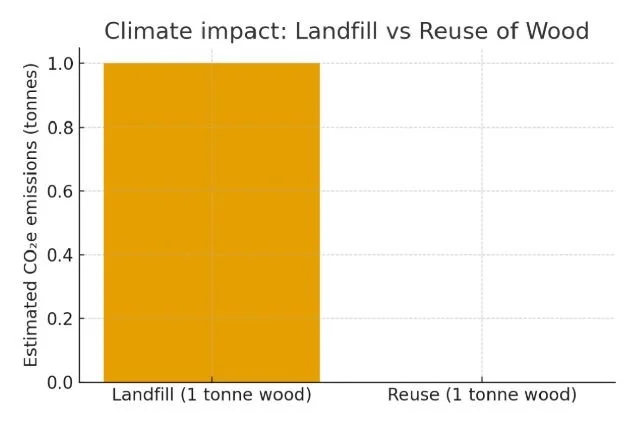

Our Modern Marquetry offcuts aren’t just wood — they’re a mix of different materials. This makes traditional recycling difficult. In landfill, wood elements break down anaerobically to produce methane (a greenhouse gas over 25 times more powerful than CO₂), while plastics and composites simply persist for centuries.

Why Resin Makes Sense

Resin has a higher footprint during production, but it creates strong, durable surfaces that:

Don’t need to be bonded to extra substrates.

Can incorporate all types of offcuts (wood, plywood, plastic, and mixed fragments).

Are suitable for take-back and reuse, keeping these complex materials in circulation.

Choosing the Right Resin

Not all resins are equal. Jesmonite, for example, is solvent-free and low in VOCs, making it safer in the studio and more environmentally considerate than traditional polyester or fibreglass resins. Some epoxy suppliers now publish lifecycle assessments (LCAs) and even offer bio-based options.

We are actively exploring these choices to ensure we minimise environmental impact while maximising performance.

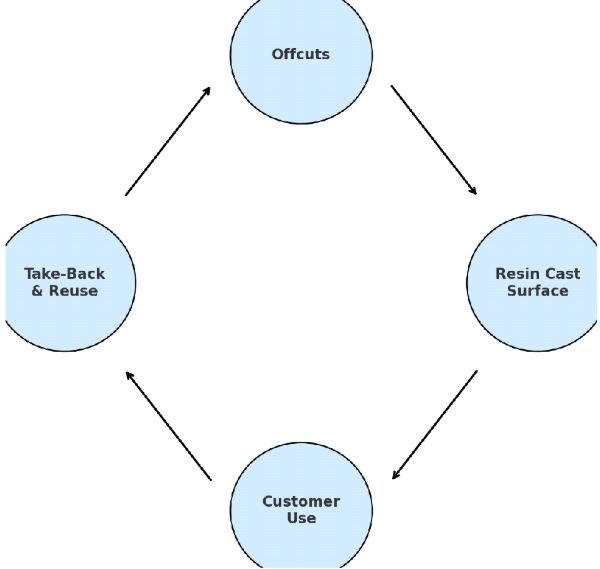

Closing the Loop: Our Take-Back Scheme

Material choice is only half the story. We’ve committed to a take-back scheme for every cast surface we produce. When a piece reaches the end of its life, customers can return it to us — and we’ll reuse or recycle it rather than send it to landfill.

Our Conclusion

After carefully weighing the options, we believe resin-cast surfaces are the most responsible way to handle our Modern Marquetry offcuts. By:

Diverting mixed-material waste from landfill,

Locking it into durable, long-lasting products, and

Taking responsibility for the end of life through take-back,

…we are creating a truly circular solution.

This is just the beginning. We will continue to measure our impact, share our data openly, and refine our material choices as new innovations appear.